Universal Robot of your choice. Send us yours or get one from us!

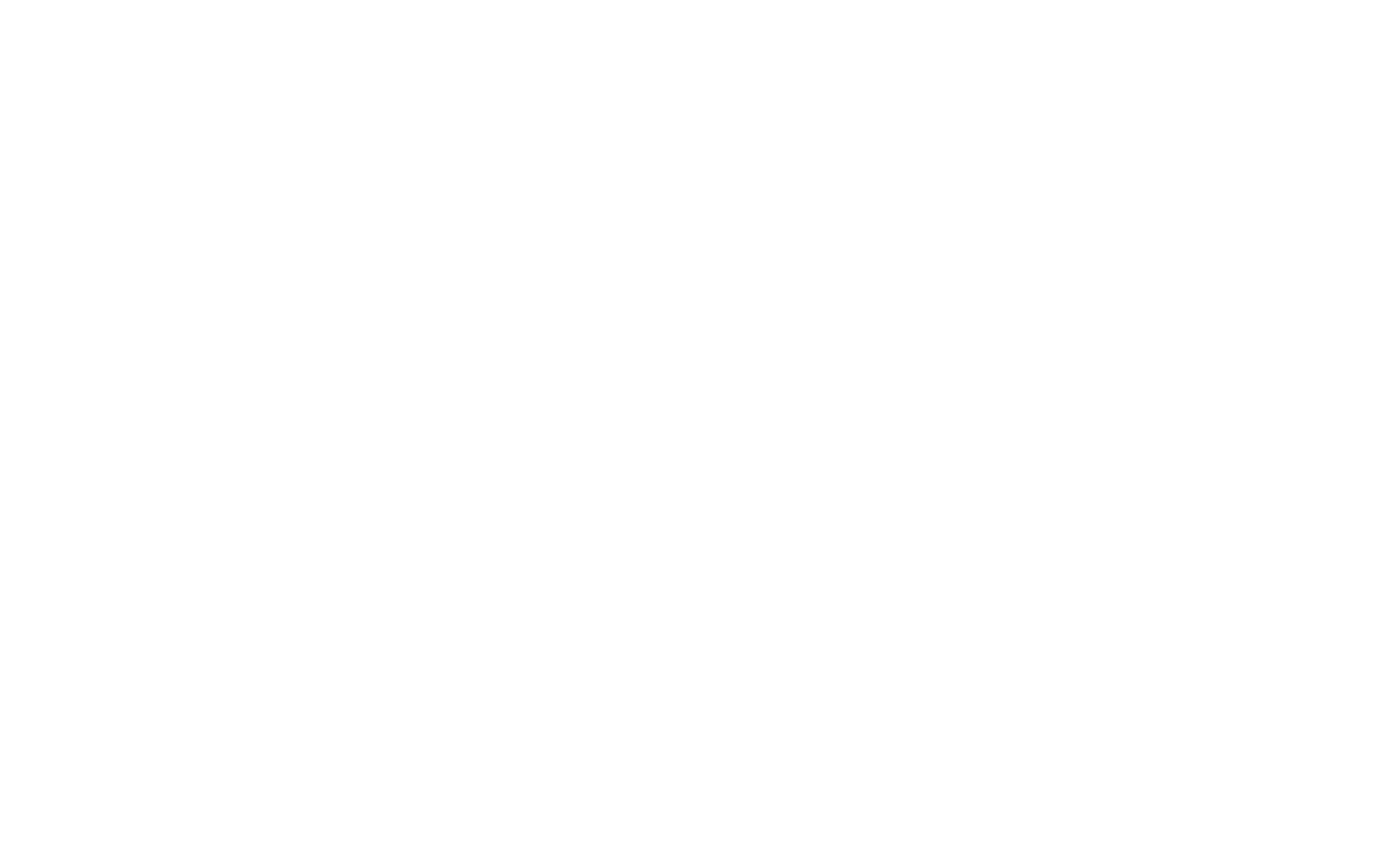

Precision Mobile Robot Stand

Heavy-duty welded and powder coated steel construction

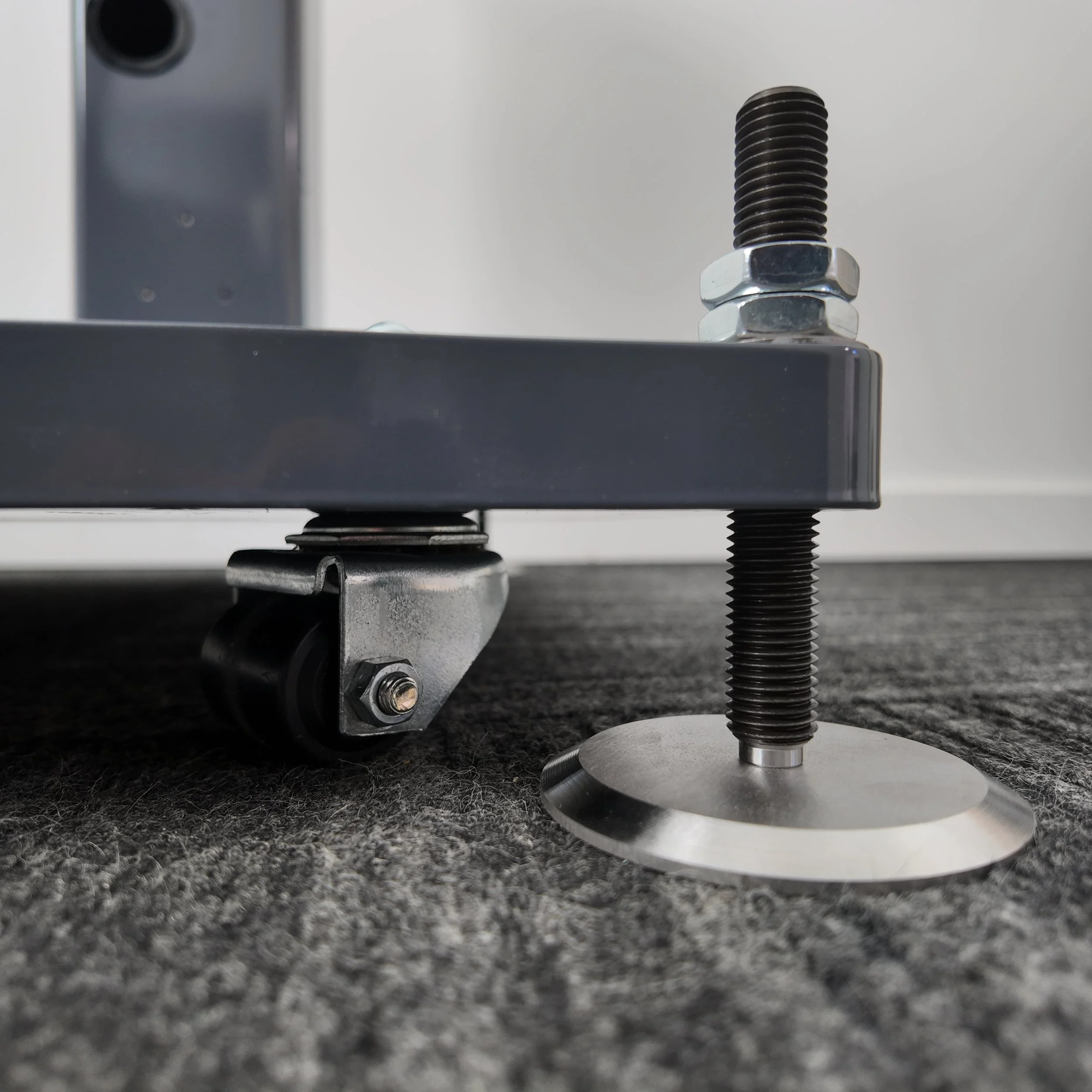

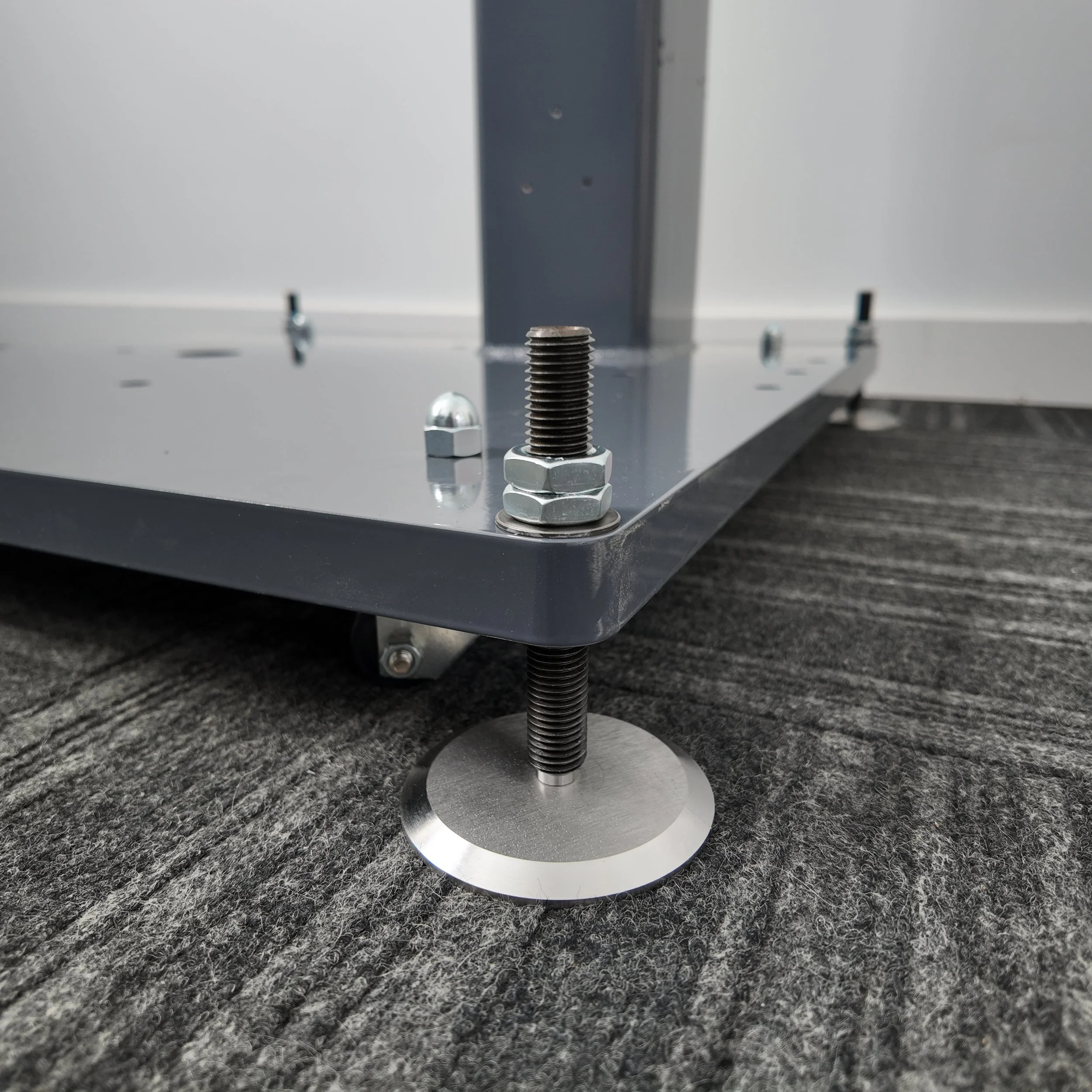

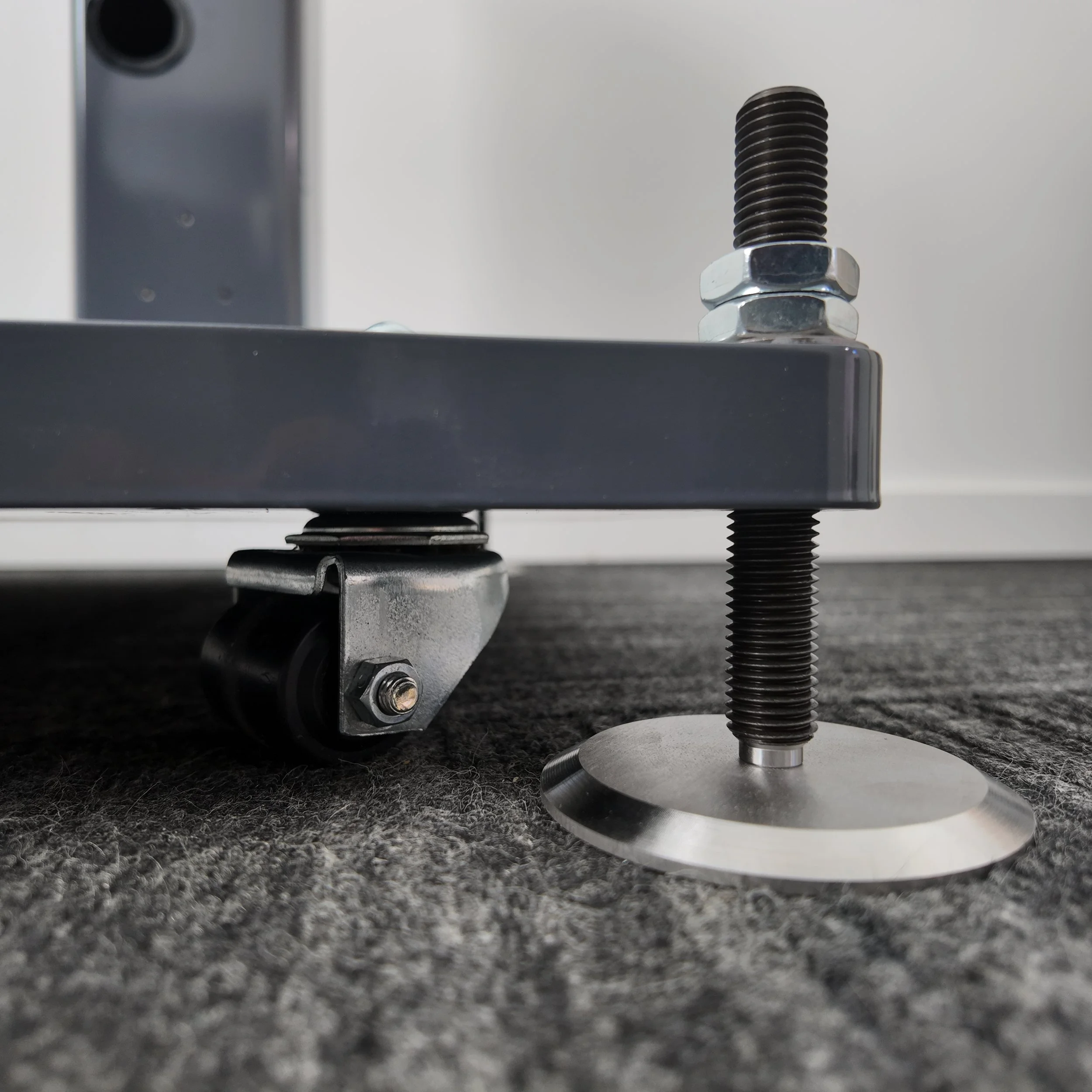

Glides on smooth rolling low profile casters

Adjustable precision steel leveling feet

Cobot pendant and pneumatic valve mounting kit

1/4" thick stainless steel floor plates for stand positioning

Enables you to move the stand & return to its precise location

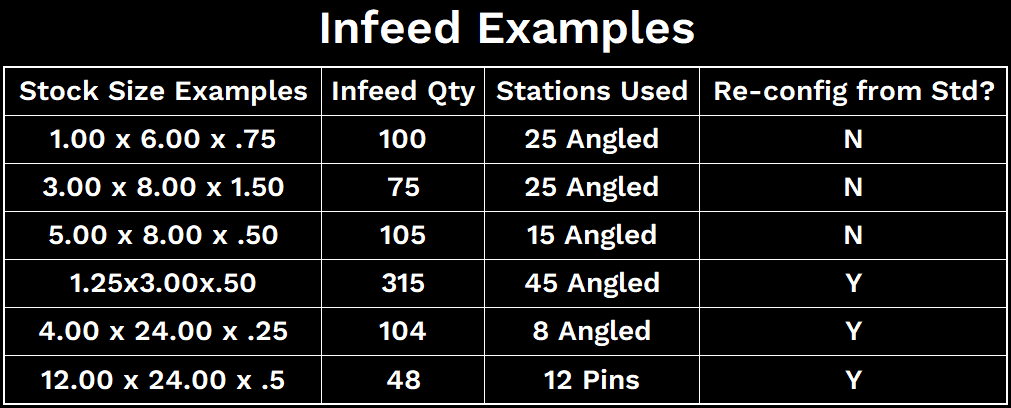

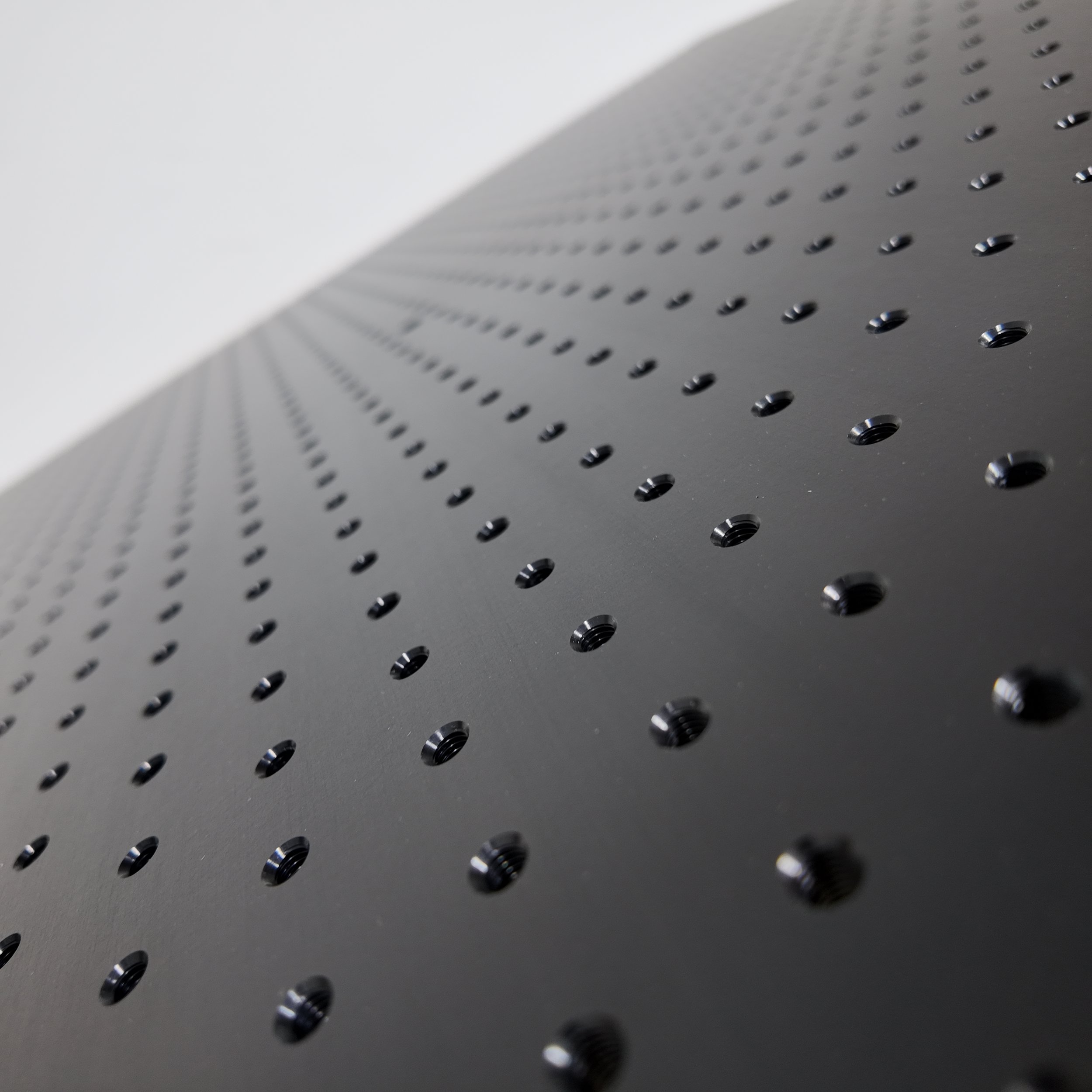

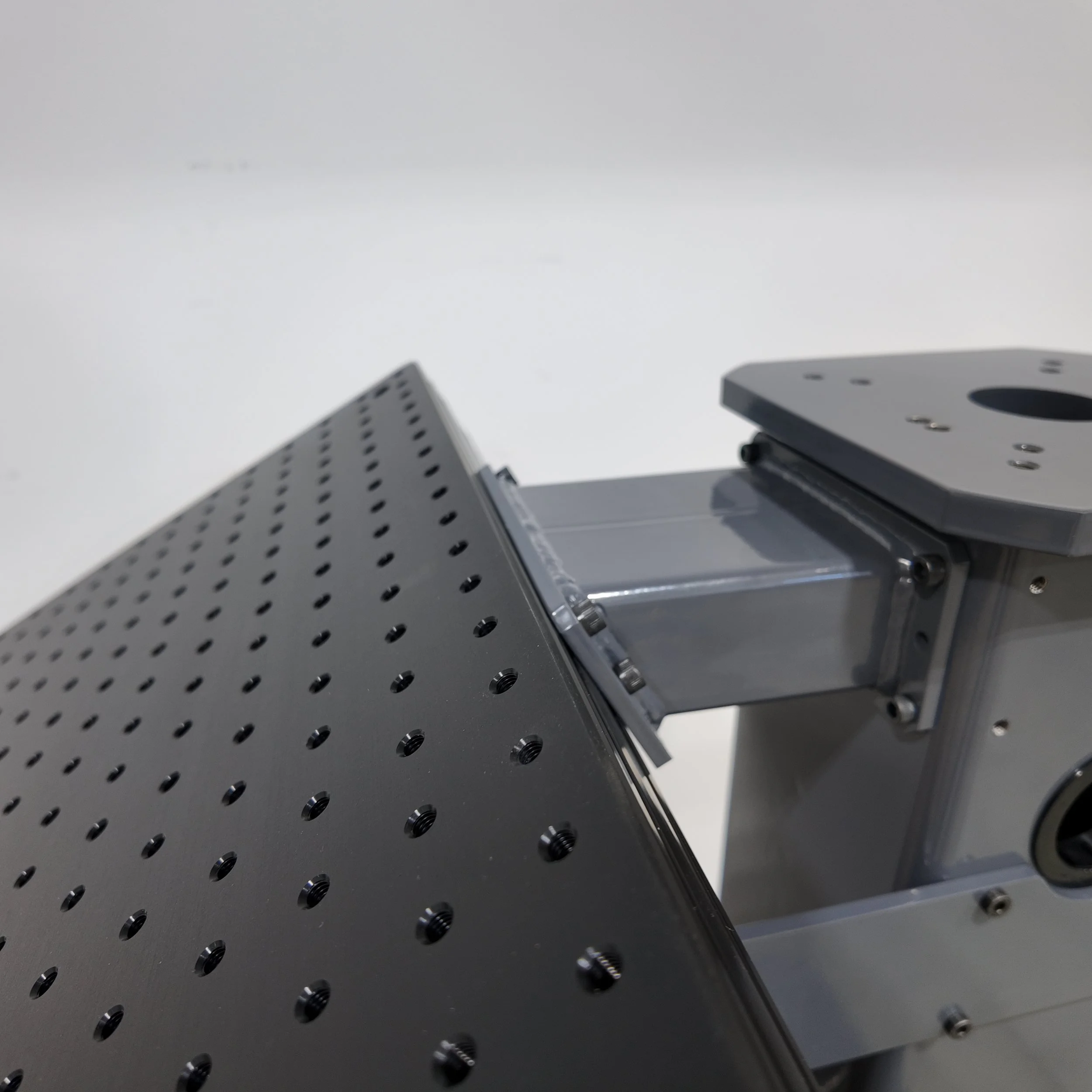

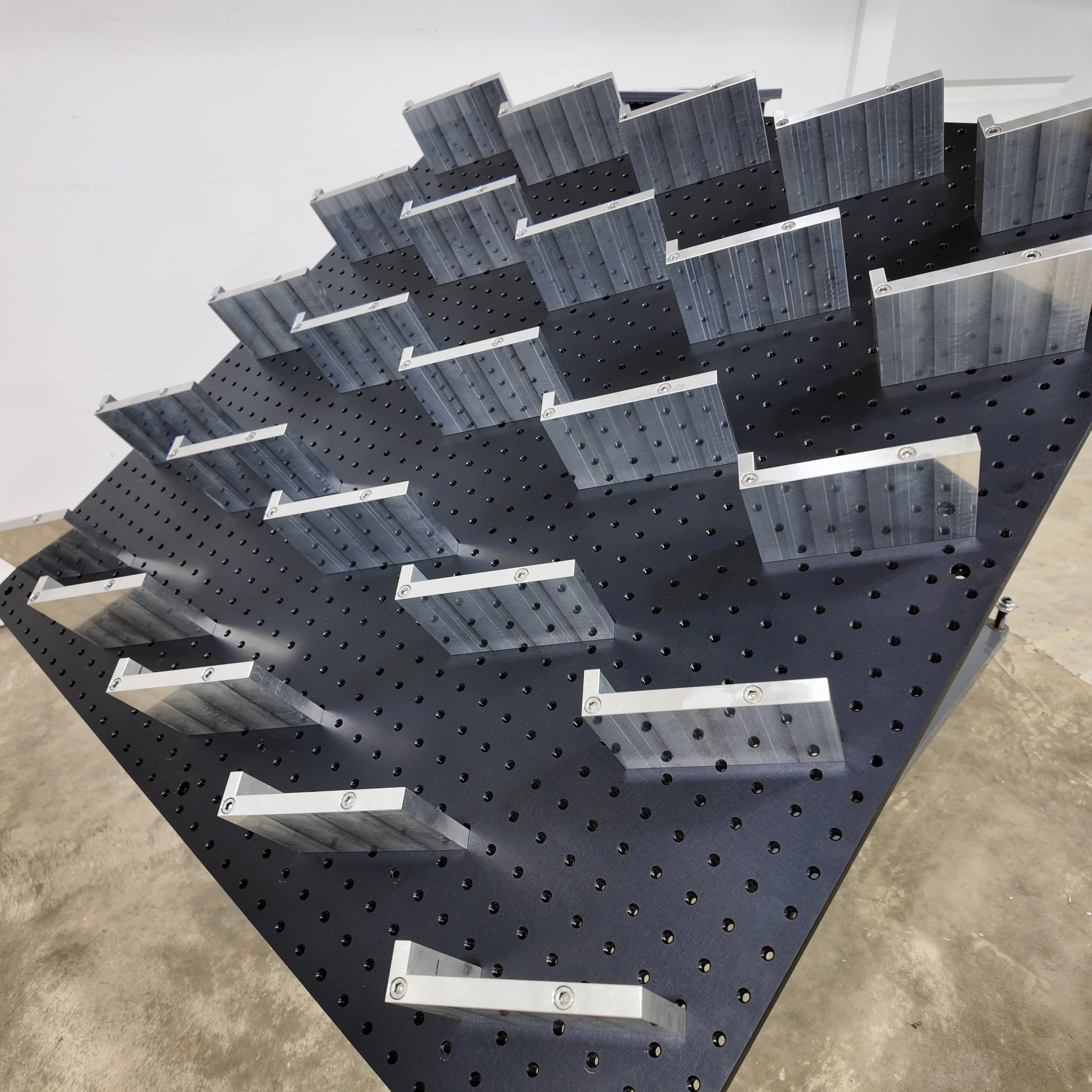

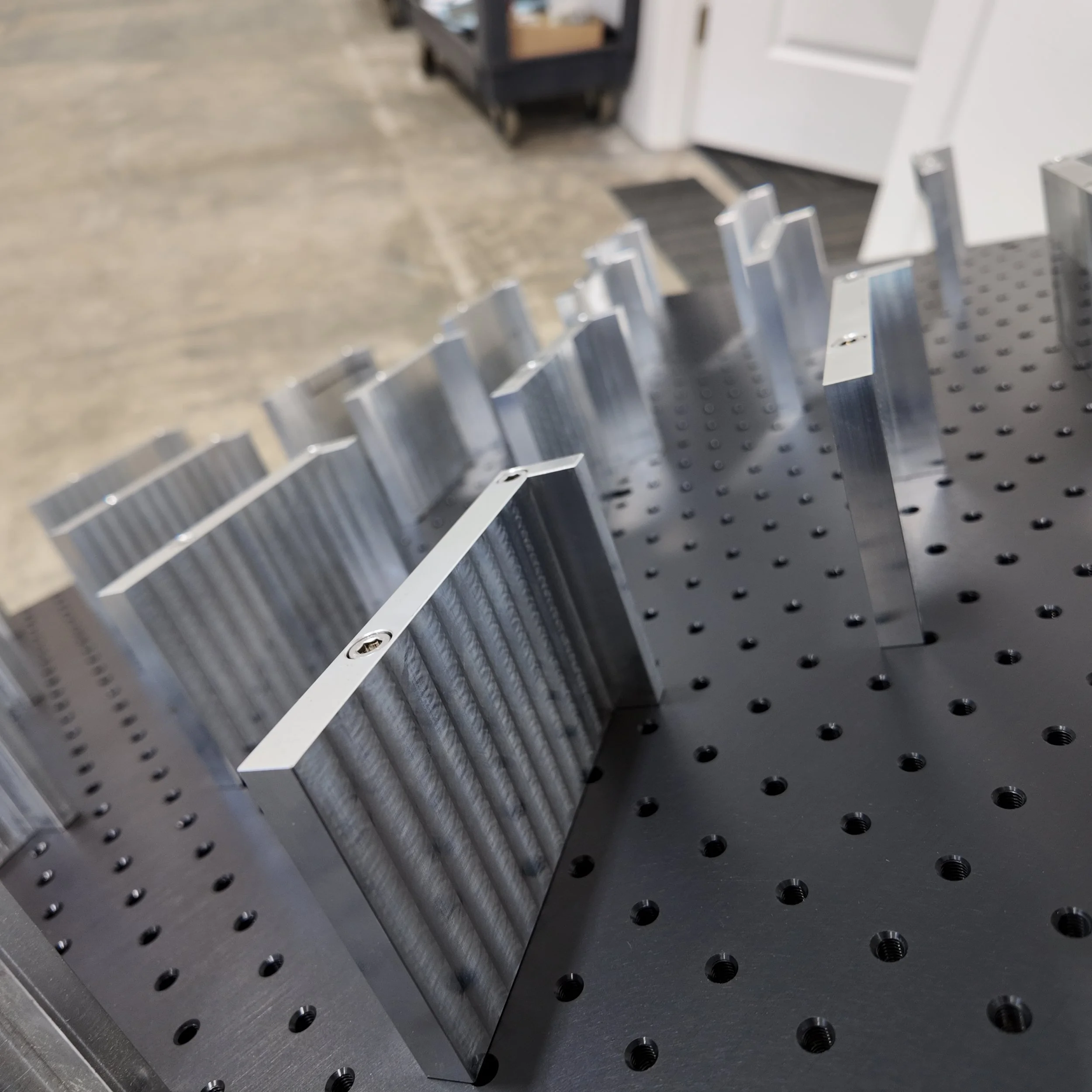

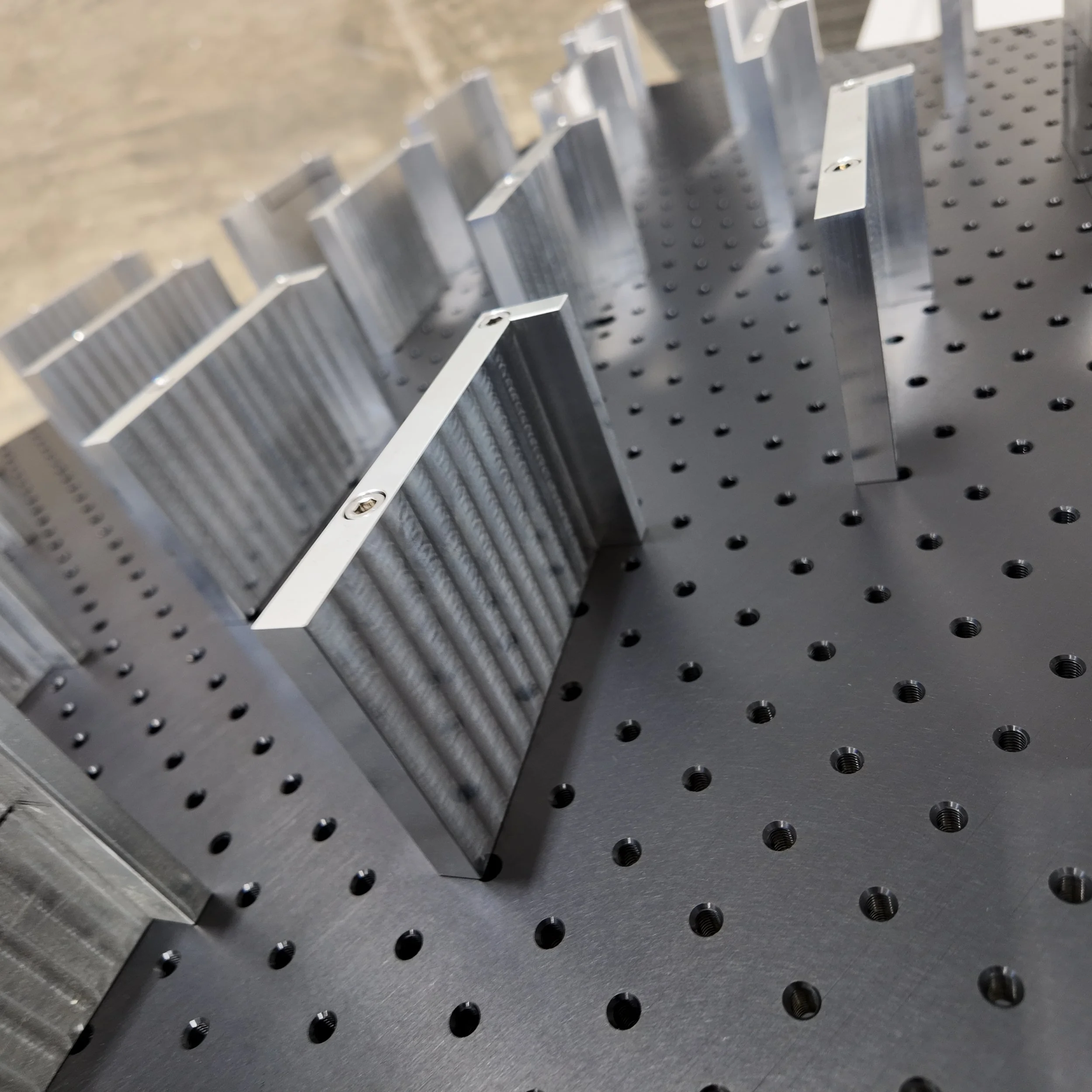

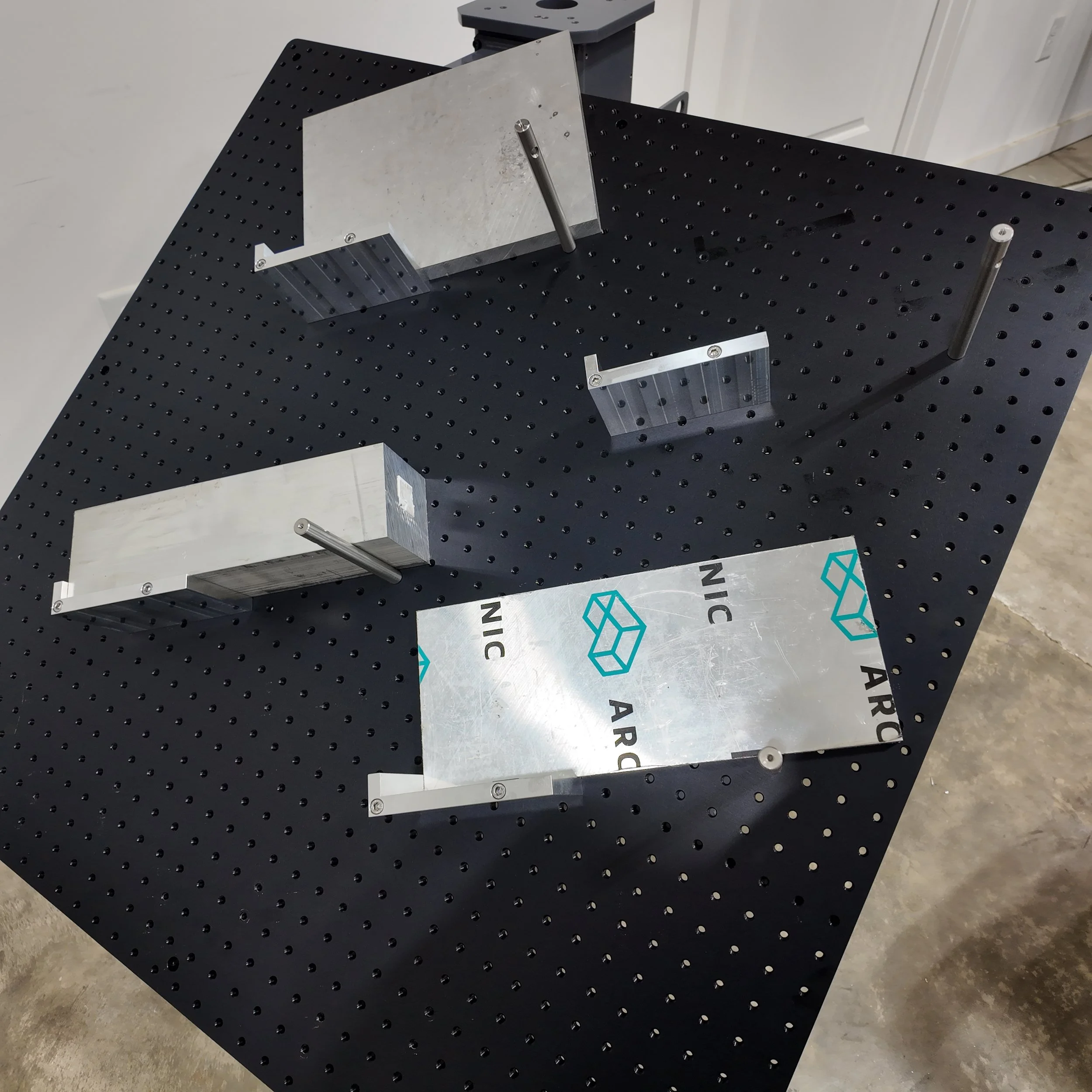

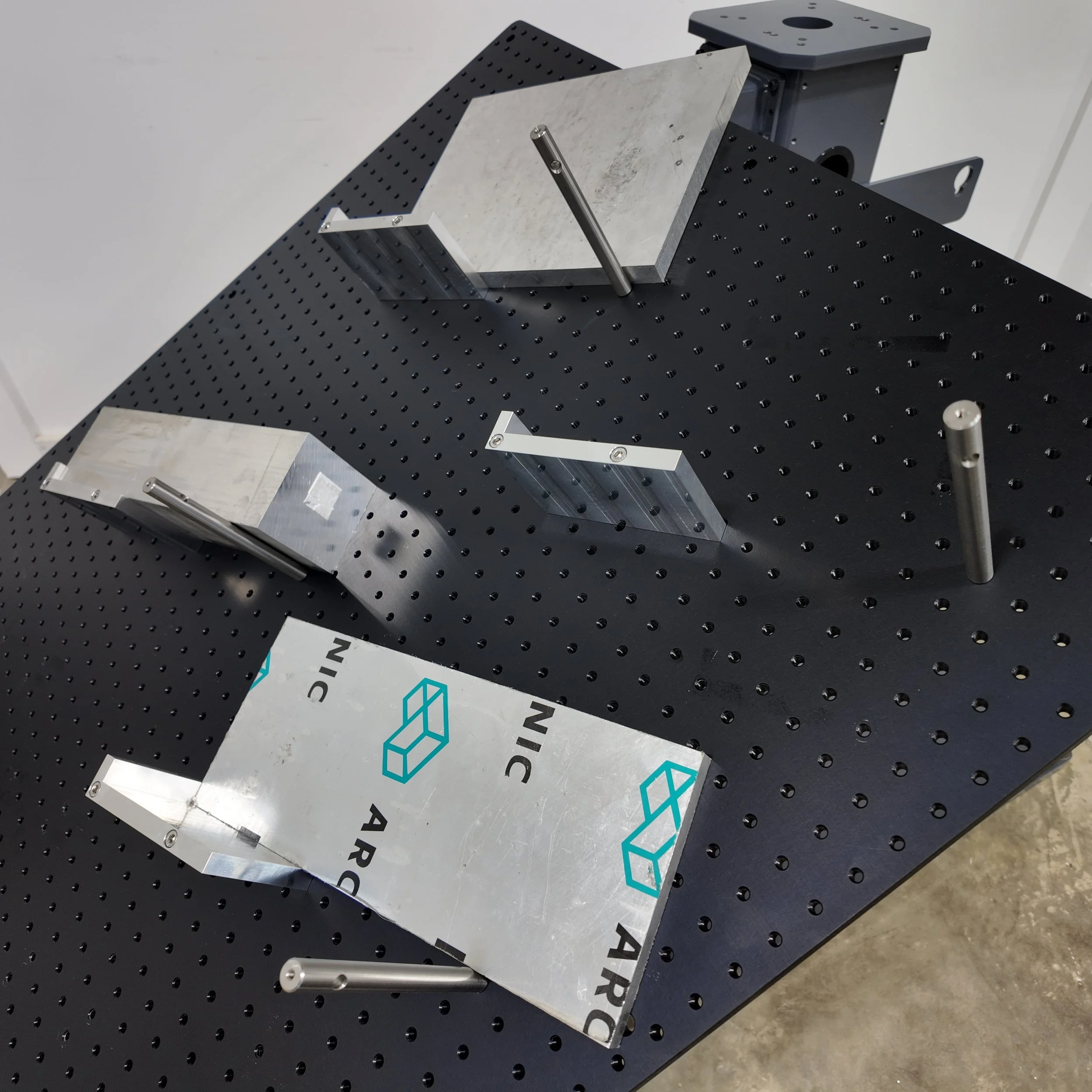

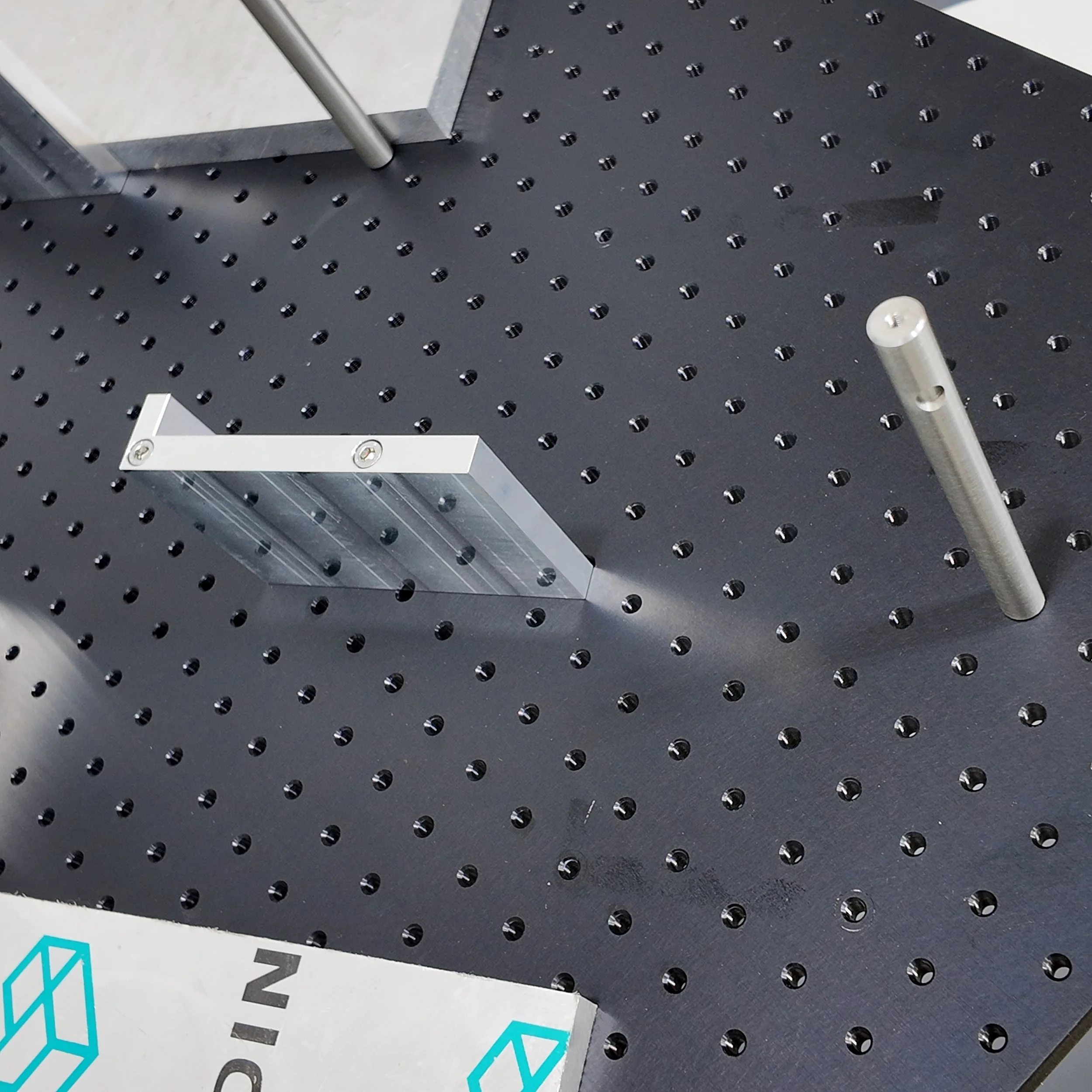

3' X 3' ARIES GRID INFEED

6mm tapped holes with 25mm grid spacing on anodized aluminum plate

Easier to program the robot in metric units

Necessary hardware, brackets & supports to mount to the robot stand rigidly

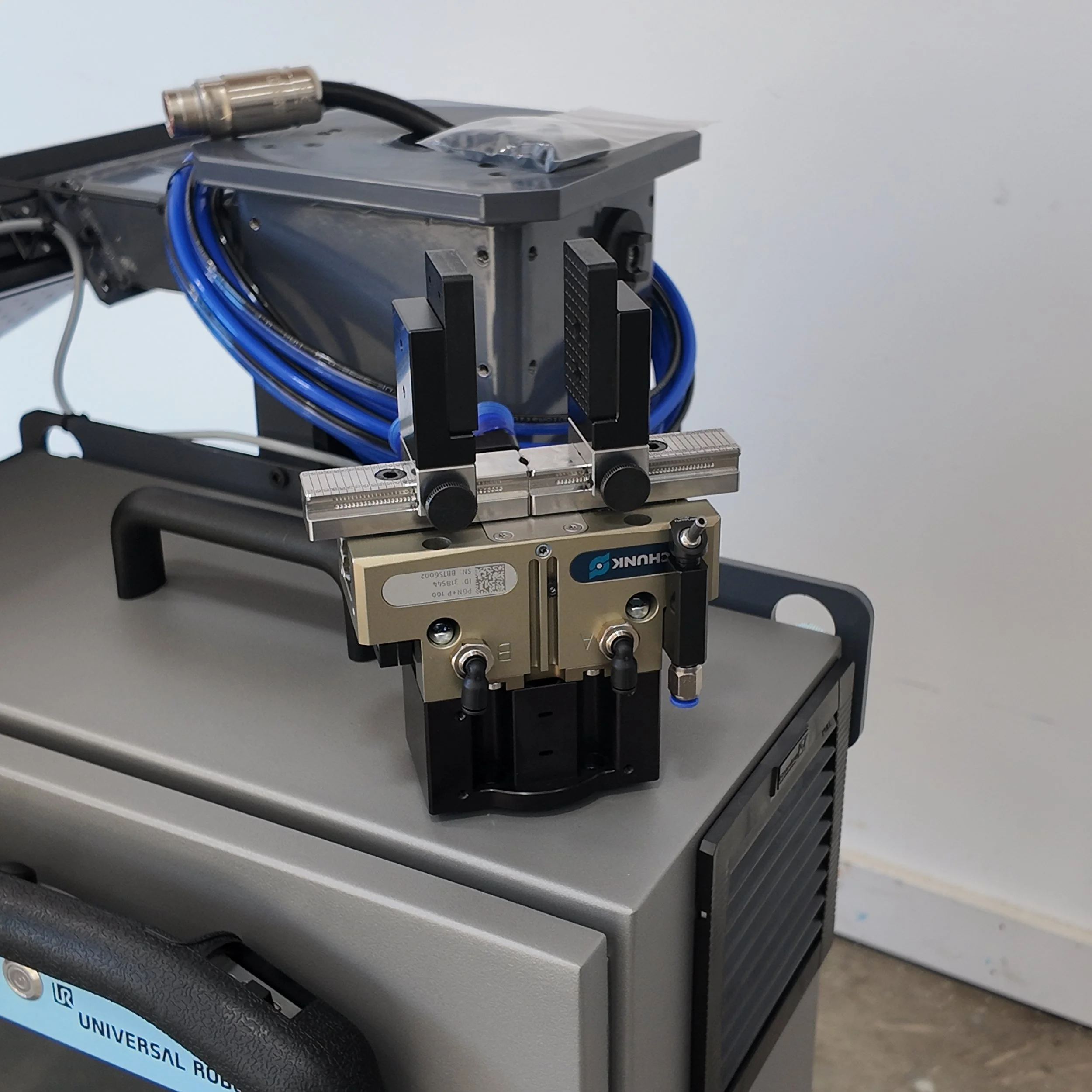

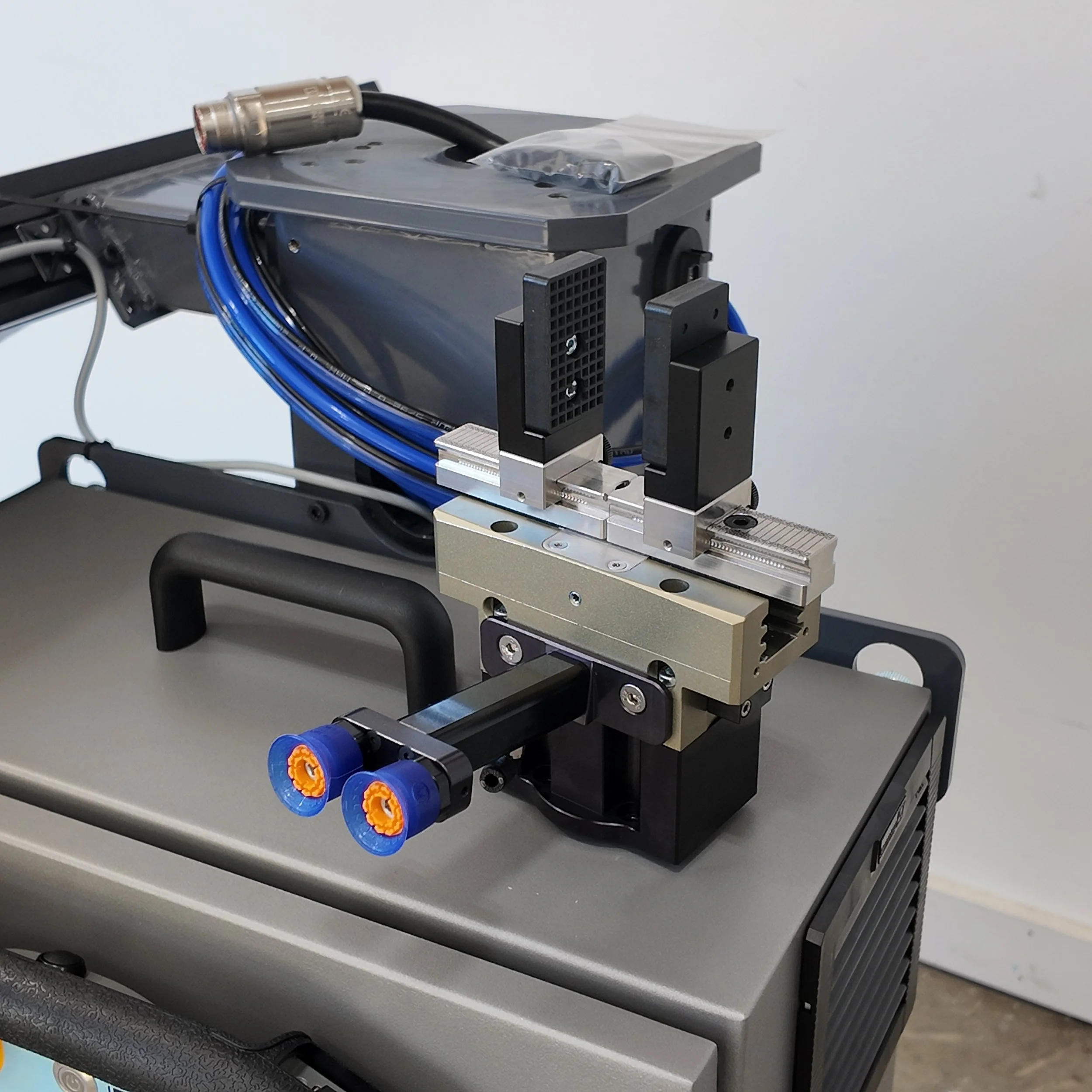

Precision Pneumatic Gripper Assembly

A two-finger parallel pneumatic gripper

0.787" travel per finger at up to 100 lbs of force

Integrated sensor and cable

Robot adapter with air blast

Easily adjustable stainless dovetail rail system

Rubber fingers for reliable part handling

A Vacuum gripper

Dual 1" suction cups at an ideal angle for infeed clearance

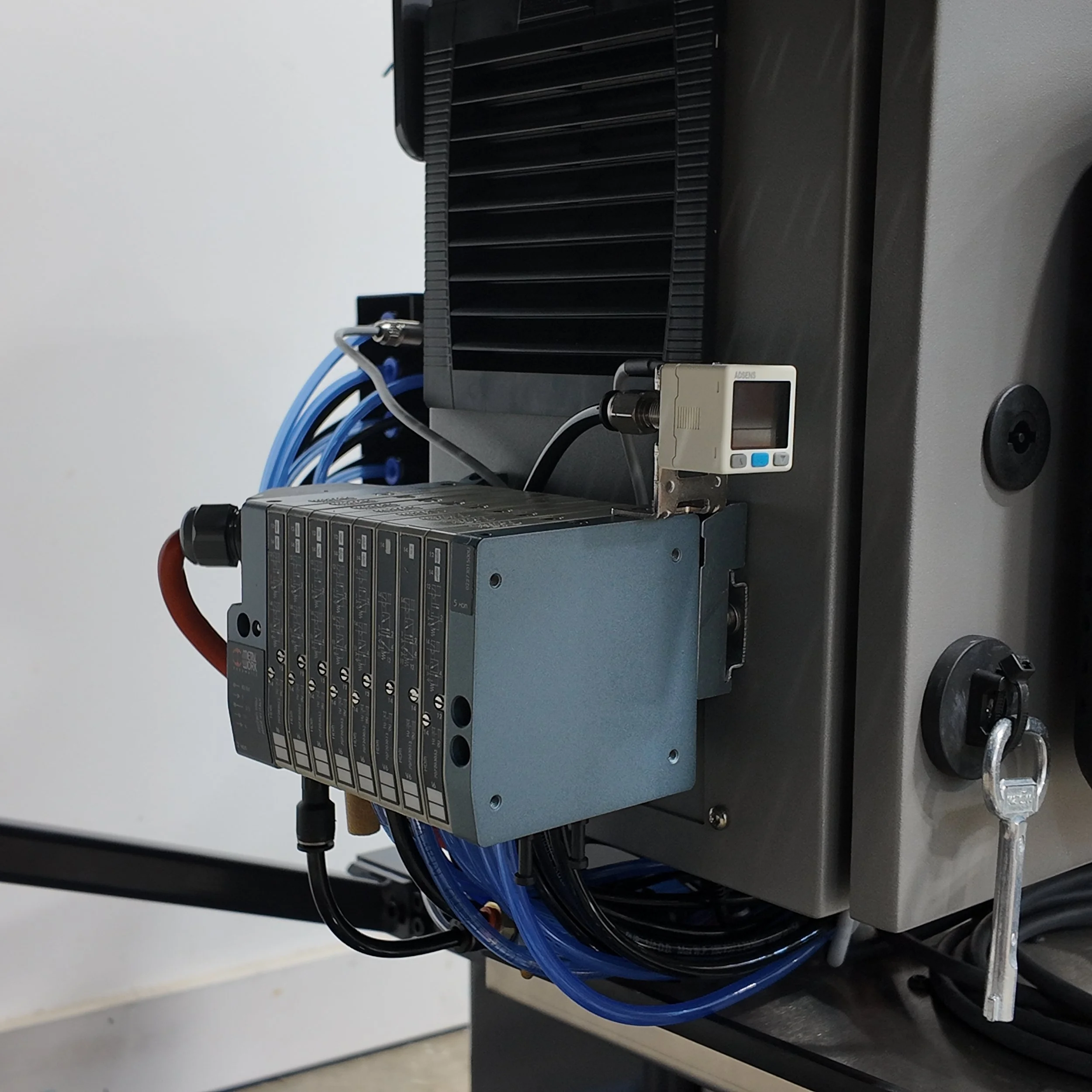

Pendant Protection

Includes a Roboworld™ high-impact rubber case for the robot pendant to enhance durability on the shop floor.

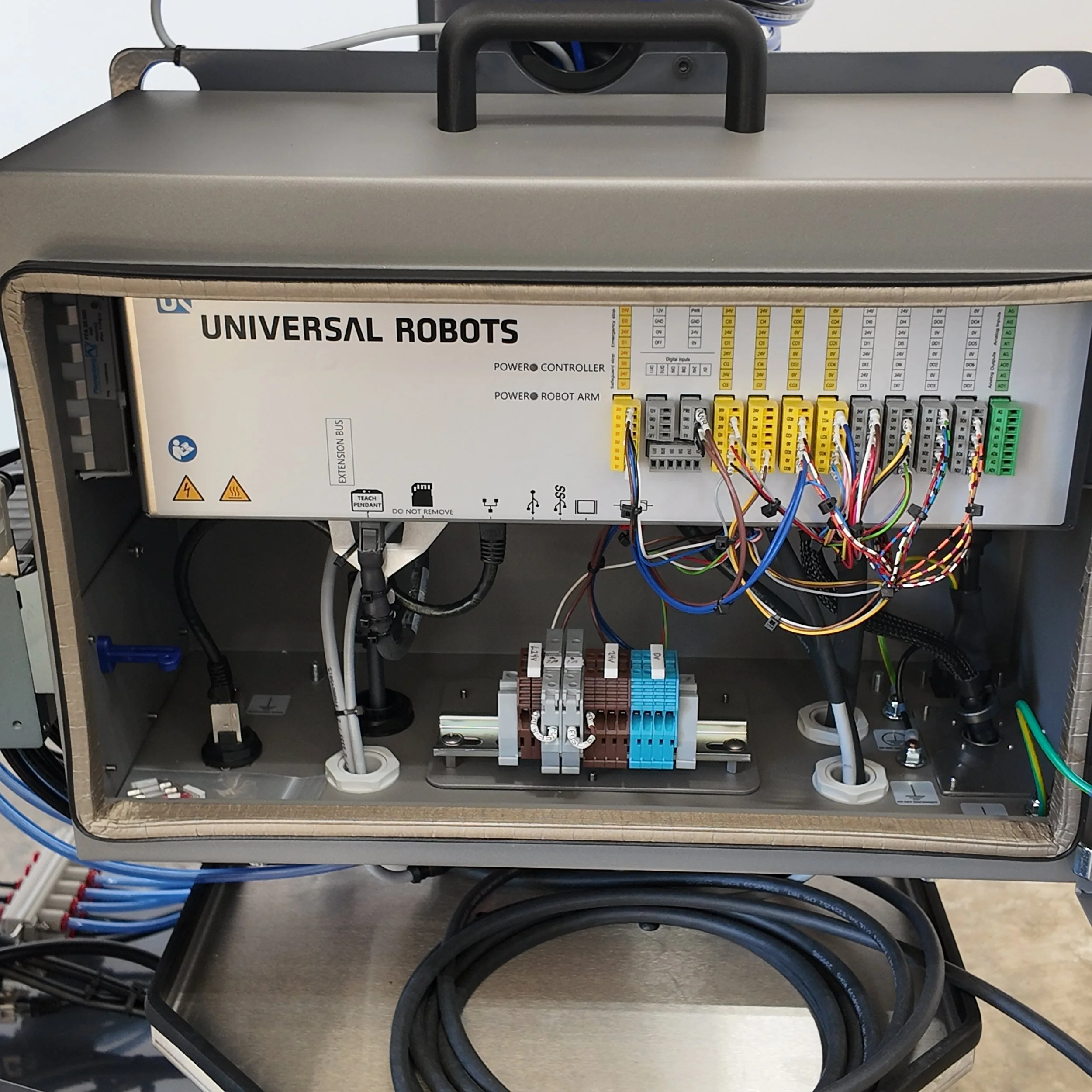

Robot-Machine Interface

CNC Link

UR CAP for 1 UR serial #

Read/Write Macros to the machine

NC program selection

Ethernet Cable

Cycle Start Relay Kit

Ability to cycle start the machine from robot program

Interface Relay

M12 female to pigtail cable

M12 male to pigtail cable

Locking Grommet

3meter M12 male to female cable

6" long black wire

6" long brown wire

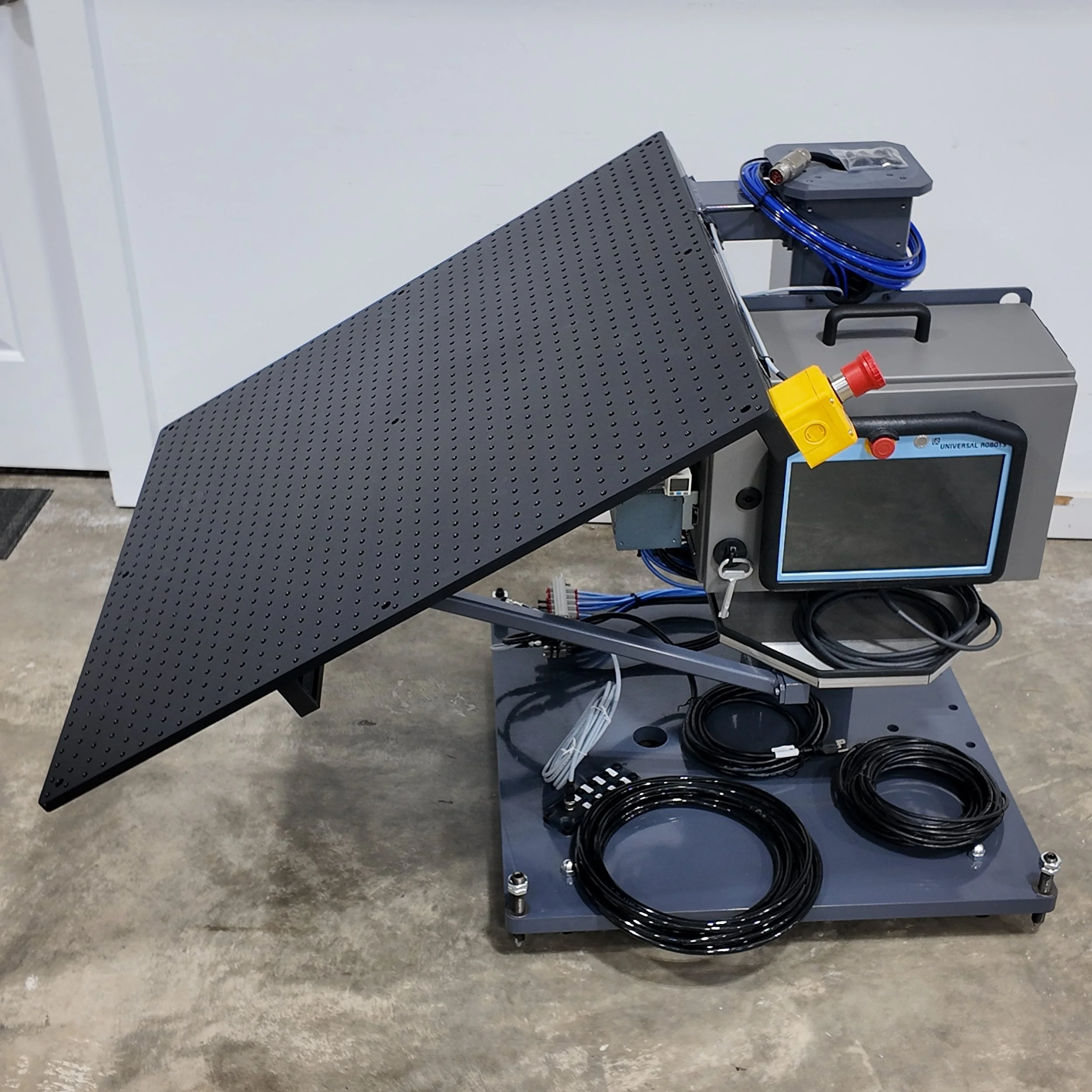

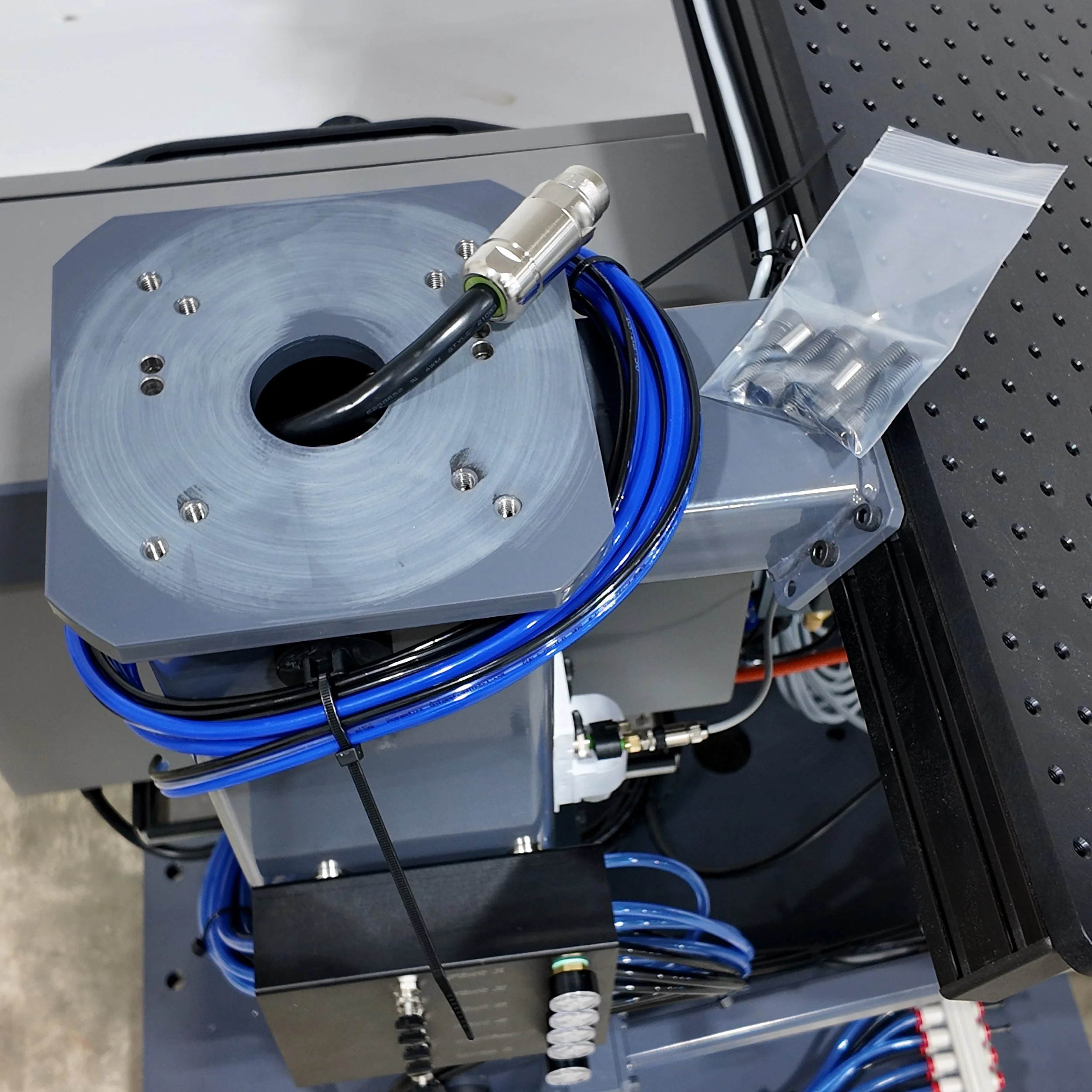

Valve Bank assembled & wired for UR win Din rail for mounting to Control Box

3/2 Pneumatic Valves, 12ea (Allows control of single or dual function pneumatic devices, and allows a neutral position)

5/2 Pneumatic Valves, 2ea (Allows control of dual function pneumatic devices without neutral position, e.g. vises that must remain clamped during power off)

I/O Power Fuse Block DIN Rail Kit

Prevents damage to the robot controller through overdraw protection

Regulator & Gauge Kit

5 Individual pressure regulators & Gauges for adjusting peripheral functions.

1 regulator and gauge set is used for adjusting the force of the parallel pneumatic gripper

Mounted on a black anodized sheet metal housing with magnets for easing mounting

Vacuum Generation & Monitoring package

Pressure Switch Assembly with 1/4" air fitting and M8 electrical plug

Allows the robot to monitor the vacuum pressure for part grip verification

Vacuum generator with 1/8" airline and fitting to connect to valve bank

Electrical Distribution Kit

M12 Junction Block located on CNC (or other remote location): Allows easy plug and play connection of 5 24V peripheral sensors and 2 24V outputs in standard M12 format.

M12 Junction Block located on Robot: Allows easy plug and play connection of up to 6 24V peripheral sensors to the robot in standard M12 format.

Cable glands for UR control box

Allows you to not have to terminate sensor wires in the robot control box by allowing you to plug them in with an M12 plug

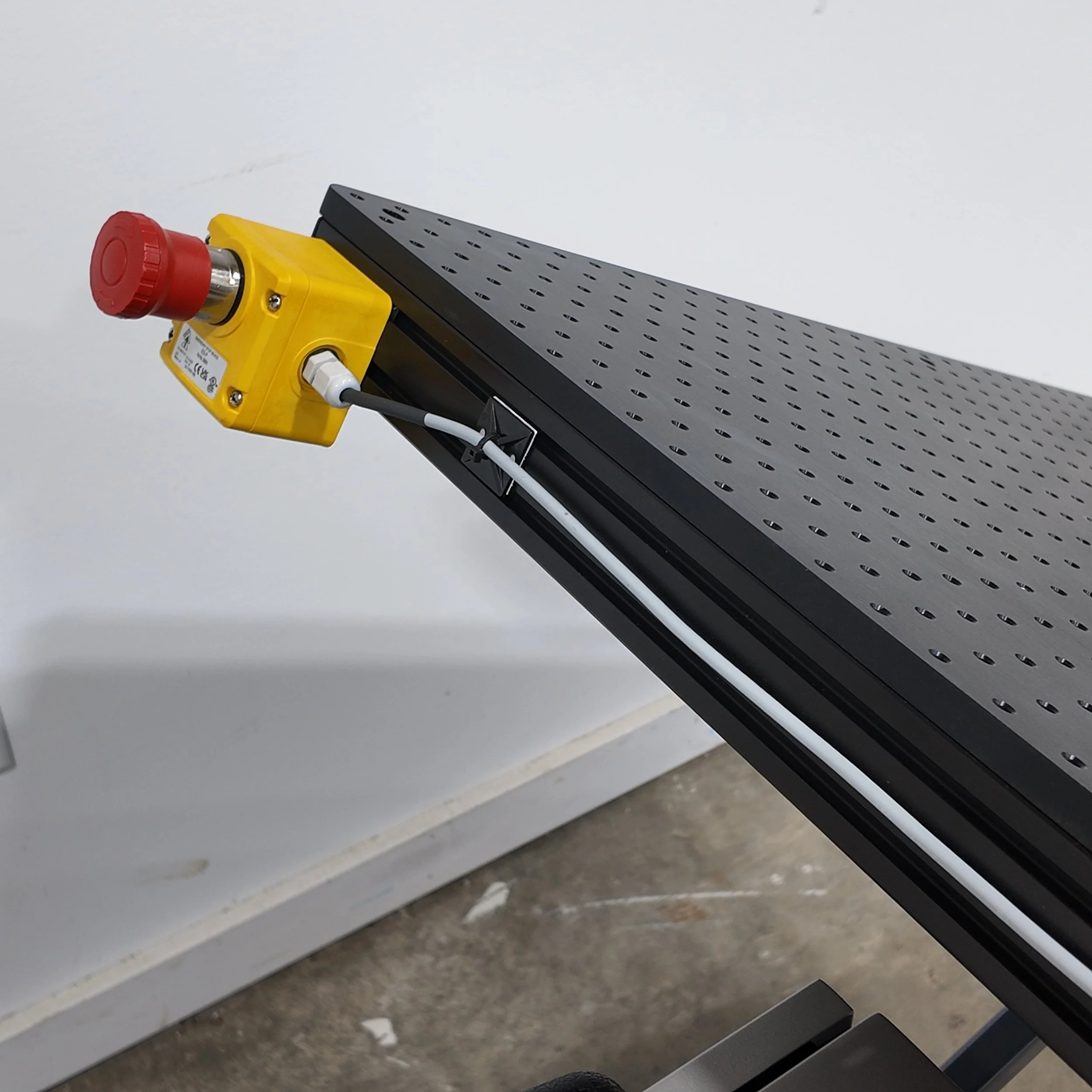

Estop button

Wired to the robot safety circuit

SICK Area Safety Laser Scanner

Includes a fully integrated SICK safety laser scanner for zone monitoring. When incorporated into a compliant safety system, it enables dynamic speed control: the robot can run at full speed when the area is clear, automatically slow to collaborative mode when someone enters the cell, and return to high-speed operation once the area is vacated.

An auxiliary input is wired to the robot for additional use cases such as cart presence detection or custom safety configuration.

Mounting bracket for Aries 12 Stand

Teach Pendant Cable Tray

Remote 10 port quick disconnect airline connector

Unplug all pneumatic peripherals with one connection.