-

Technical Documents available upon request

-

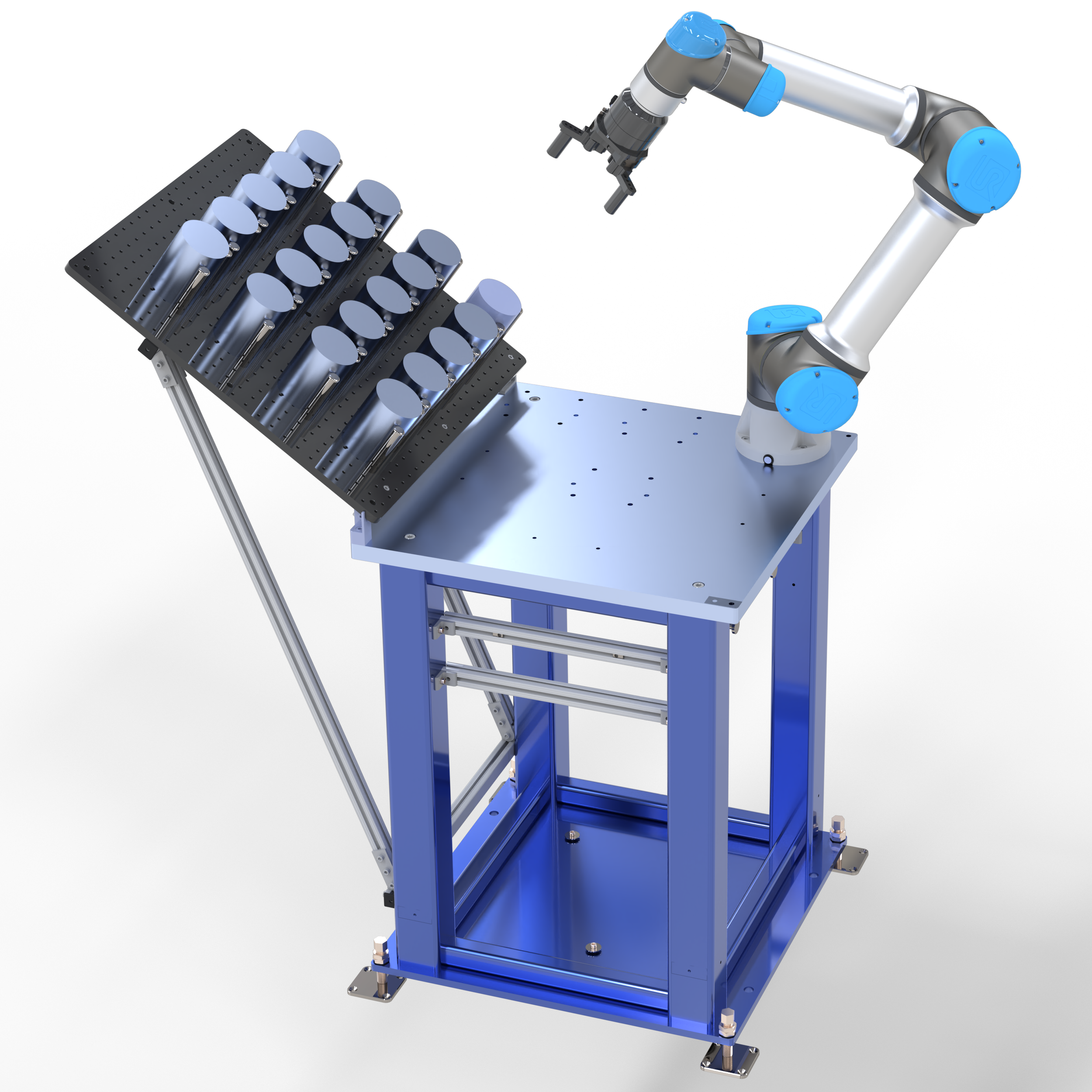

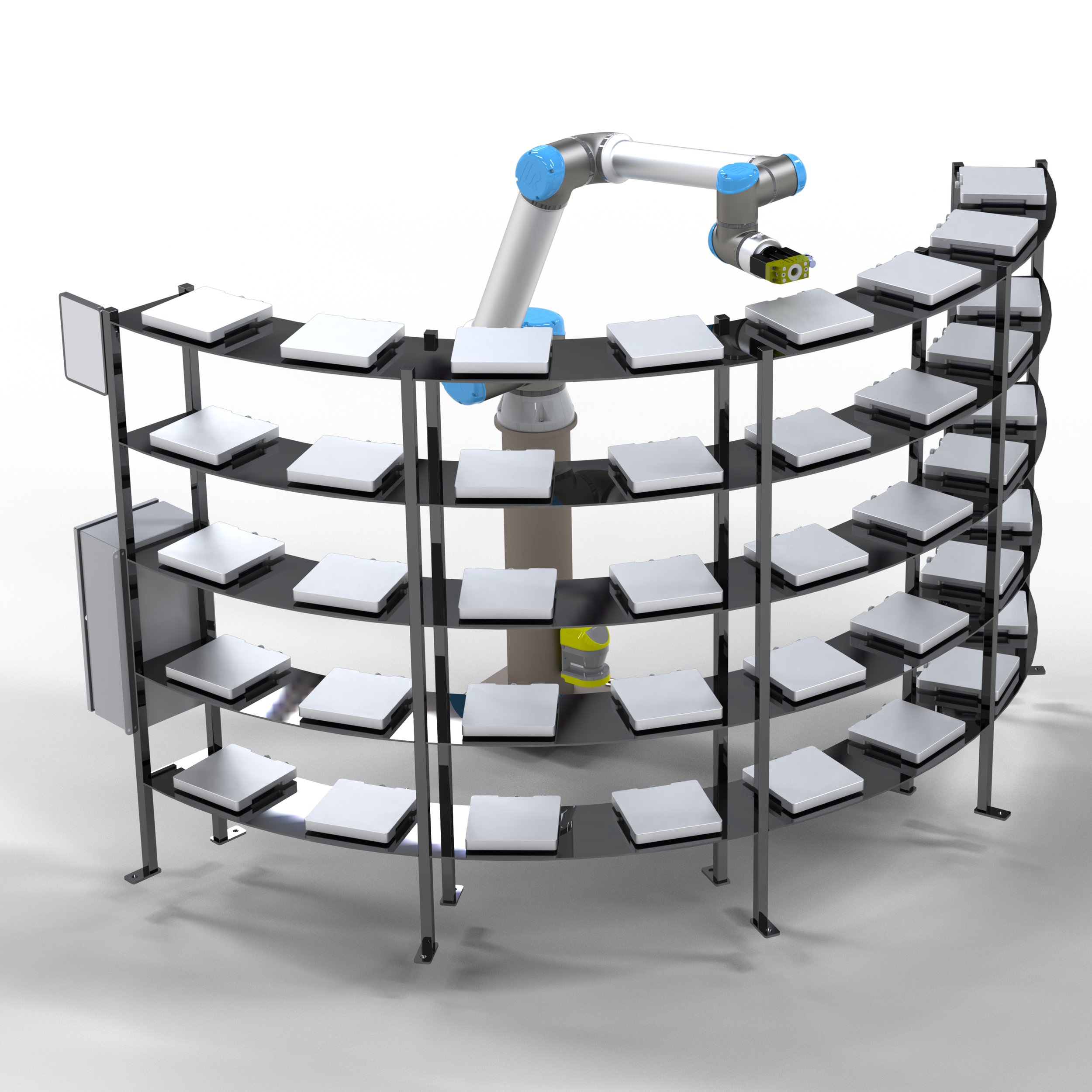

•Universal Robots UR5e Collaborative Robot

o Payload: 11 lb. (5kg)

o Reach: 33.5” (850mm)

o repeatability +/- 0.0012” (±0.03mm)

• Part Payload 7.7 lbs.

• System Requirements

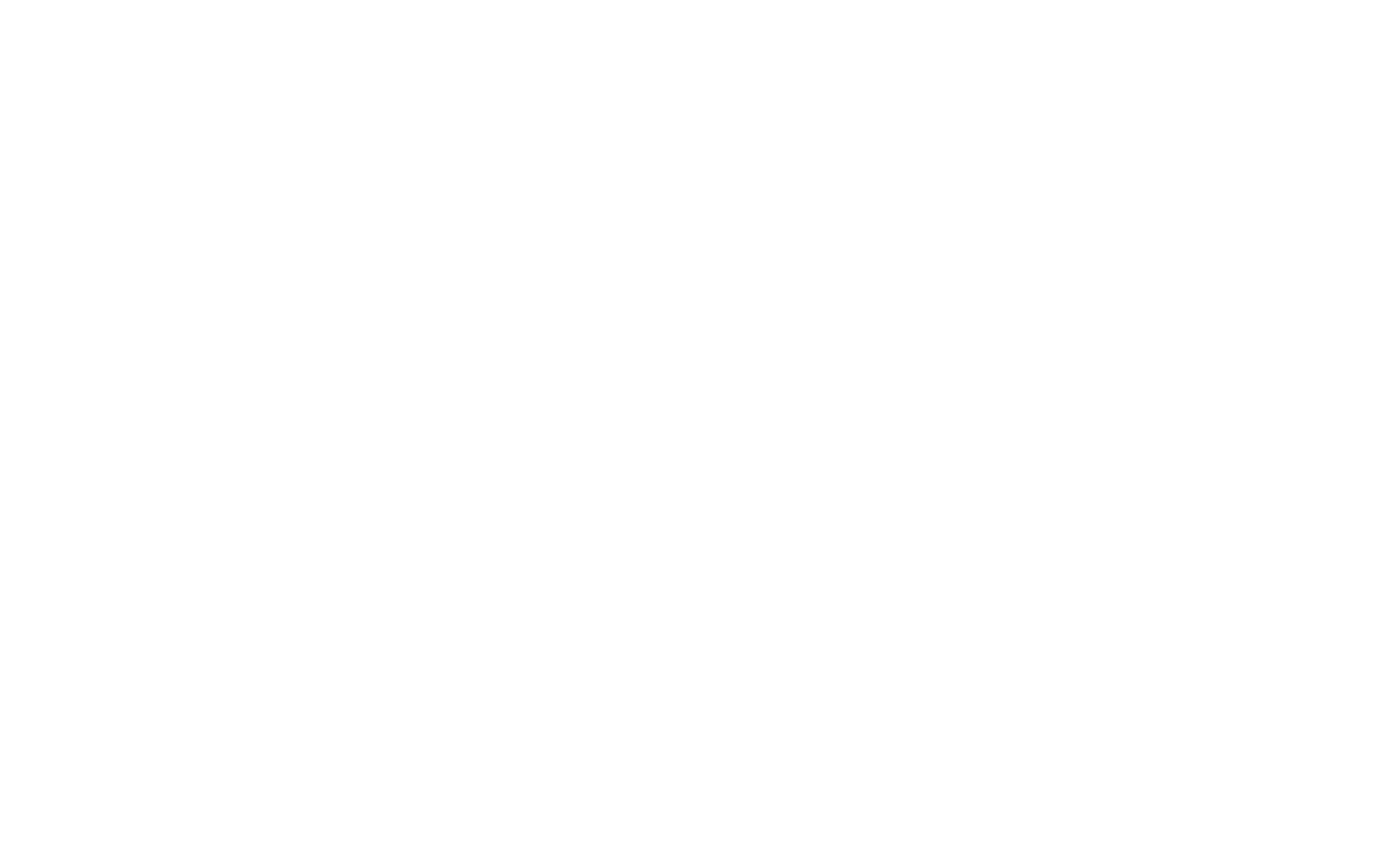

o Floor Space: 40”wide x 24” deep (3-6” from machine) x 60" tall

o Air requirements: 2.5 CFM @ 100psi

o Electrical requirements: 120 VAC 15A -

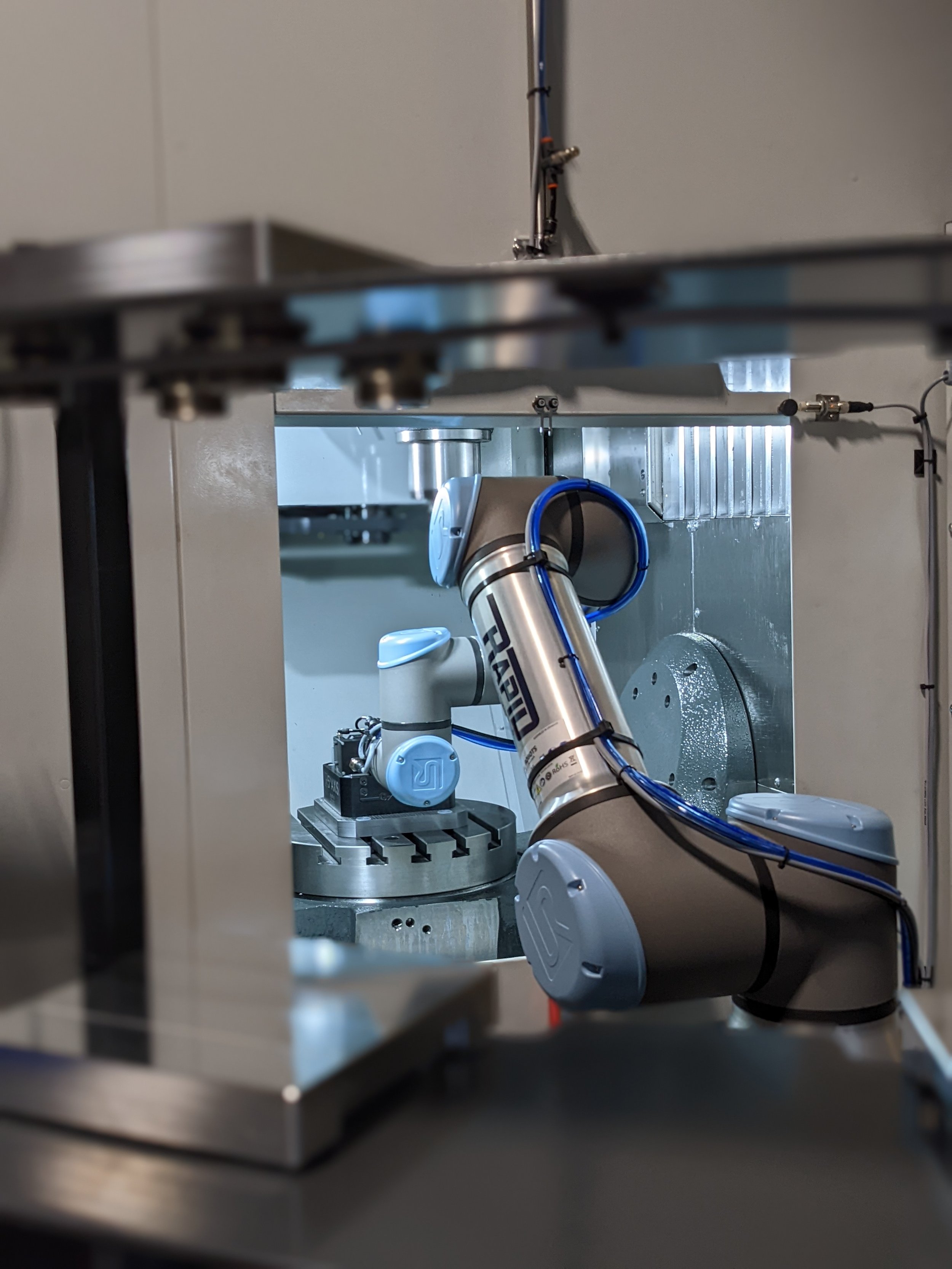

• Precision pneumatic concentric gripper with teachable opened/closed sensor, and adjustable fingers

• Seamless CNC communication via Ethernet allowing for precise control of NC program selection, chuck open/close commands, cycle start, and the ability to read and write macro variable to/from the machine.

• Air-blast nozzle for cleaning of parts and vise/chuck jaws

• A configurable inclined grid infeed system to fit a wide variety of part sizes and shapes in a high density layout

• An ultra heavy duty welded steel robot stand with casters allows you to effortlessly push your robot between work cells

• Low profile floor plates and steel leveling bolts allows you to quickly relocate the system repeatably

• Well-polished pneumatics and wiring for smooth and efficient operation

• Outfeed Cart with Presence Sensor to seamlessly move finished parts around your shop

• Systems are typically sold with turn-key robot programming & system installation to get you running lights out is record time with reliable loading and unloading of parts

• Inclusive advisory safety risk assessment per ISO 10218-1, 10218-2, 12100, TS15066, 13850, and 14120 to ensure compliance and safety

• Before installation, our team will work with you to ensure your shop is prepped with the necessary work holding, auto-doors, air supply & power requirements to make your experience fast and easy.